Understanding Chicken Farms with Spawners

Overview of Spawner Technology in Chicken Farming

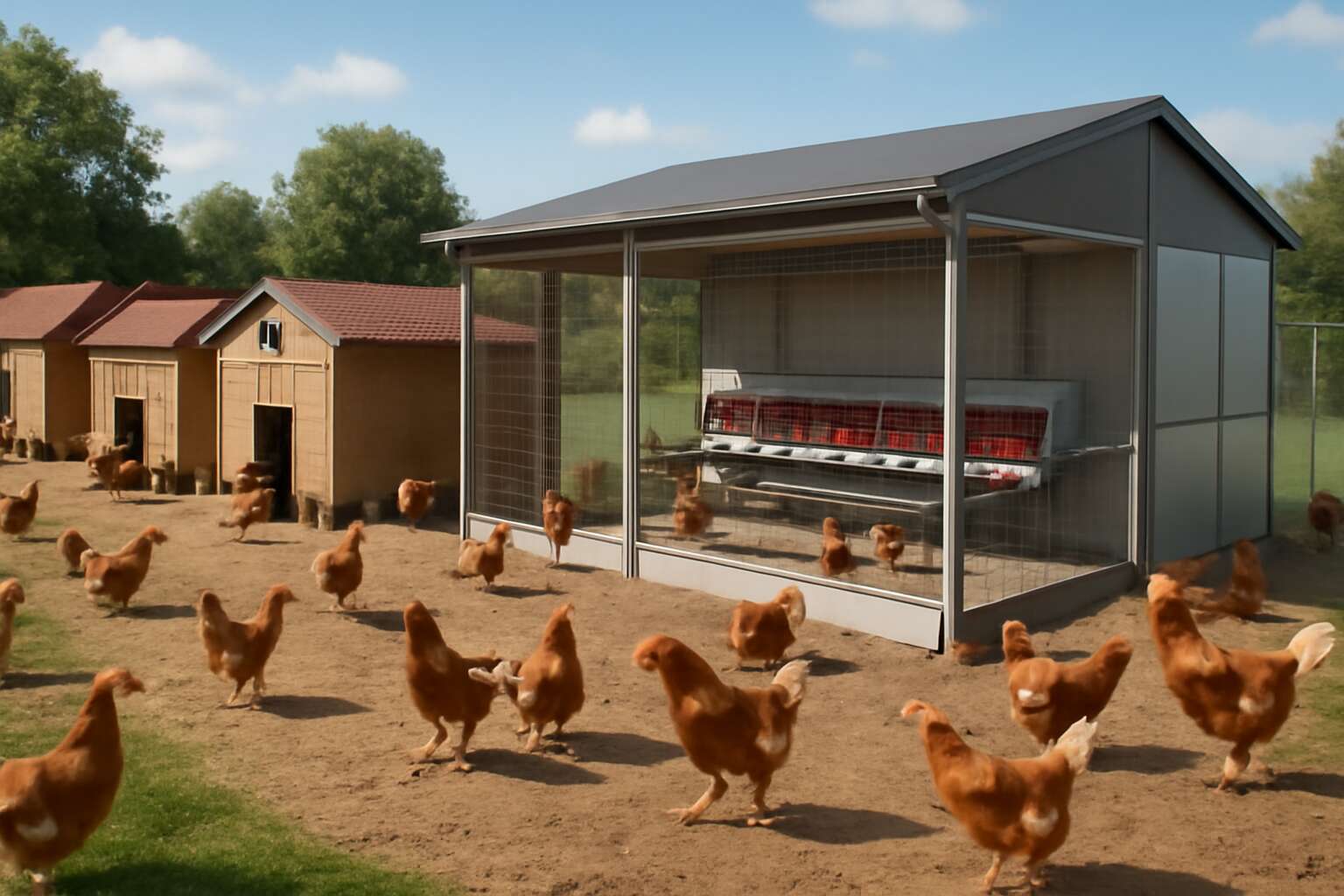

When it comes to modern chicken farms, the integration of spawner technology is akin to giving your poultry operation a secret weapon. Recent innovations have transformed traditional farm setups into highly efficient, almost futuristic enterprises. Imagine a chicken farm with spawner that not only maximises egg production but also streamlines the entire process—sounds like a dream, right? Well, it’s becoming a reality!

Understanding the core of spawner technology is crucial. These systems function as automated hatchery stations, rapidly increasing chick output without the mess and fuss of traditional brooding. They utilise carefully calibrated environments that mimic optimal conditions, ensuring chicks hatch healthy and strong every time. For those seeking to upscale, here are some key benefits of implementing a chicken farm with spawner:

- Enhanced hatch rates with minimal intervention

- Reduced labour costs and manual handling

- Consistent chick quality, boosting overall farm productivity

In essence, the adoption of spawner technology in chicken farming not only elevates efficiency but also offers a glimpse into the future of sustainable, high-yield poultry operations. It’s a game changer that keeps farms competitive and ready to meet the growing demand for quality poultry products.

Benefits of Using Spawners in Poultry Farms

Understanding how a chicken farm with spawner operates reveals a new level of efficiency in poultry management. These innovative systems automate the hatchery process, allowing farms to produce chicks at a faster rate with less manual effort. Unlike traditional methods, spawner technology creates an environment that closely mimics natural incubation conditions, ensuring healthier and more resilient chicks. This not only boosts productivity but also reduces the likelihood of losses due to suboptimal hatch conditions.

The benefits of using spawners in poultry farms extend beyond just increased output. They streamline operations and minimise labour costs, freeing up resources for other important aspects of farm management. For example, many chicken farm with spawner setups incorporate features such as:

- Automated temperature and humidity regulation

- Rapid chick hatching cycles

- Consistent chick quality, which enhances overall farm performance

In the broader picture, integrating spawner technology into a chicken farm with spawner ensures sustainable growth. It provides a competitive edge by delivering high-quality poultry products more efficiently, meeting the rising demand while maintaining operational stability.

Types of Spawners Used in Chicken Farming

Within the realm of modern poultry ingenuity, understanding the types of spawners used in chicken farming unveils a tapestry of possibilities that elevate a chicken farm with spawner to new heights. These devices, crafted with precision and care, are the heartbeat of automated hatchery systems, transforming traditional methods into a symphony of efficiency and consistency.

Among the most prevalent are incubator-style spawners, which replicate natural incubation environments through sophisticated temperature and humidity controls. These are often complemented by advanced automated systems that ensure optimal conditions, resulting in rapid and reliable chick hatching cycles. On the other hand, there are modular spawners designed for flexibility, allowing farmers to customise their setups depending on flock size or specific breed requirements.

To better appreciate the diversity, consider these common types:

- Conventional incubator spawners: utilise controlled environments to mimic nature’s warmth and moisture.

- Automated egg turning spawners: ensure even incubation by gently rotating eggs at regular intervals.

- Hybrid systems: combine features of traditional incubators with modern automation, perfect for scaling a chicken farm with spawner.

Each type plays a vital role in streamlining the hatchery process, making the chicken farm with spawner not only more productive but also more resilient in the face of fluctuating demand and environmental challenges.

Designing an Efficient Chicken Farm with Spawner

Key Components of a Spawner-based Chicken Farm

Creating a truly efficient chicken farm with spawner isn’t just about throwing some eggs into a coop and hoping for the best. It’s a delicate dance of engineering, biology, and a dash of mad scientist ingenuity. The key components of a spawner-based chicken farm are meticulously designed to optimise output while minimising effort — and yes, avoiding the dreaded “chicken chaos”.

Central to this setup is the spawner system itself, which functions as the heartbeat of the operation. When properly calibrated, it ensures a steady stream of chickens without the farmer’s constant intervention. Alongside this, a well-thought-out layout incorporating automatic feeders and water dispensers streamlines the process, turning what used to be a manual labour nightmare into a smooth, almost robotic, operation. Achieving this requires understanding the specific behaviour of chickens and integrating technology that mimics their natural instincts, but with a modern twist.

To optimise productivity, consider these essential elements:

- Strategic placement of the spawner for maximum coverage

- Efficient utilisation of space to prevent overcrowding

- Automated systems for feeding, watering, and egg collection

With these components working in harmony, a chicken farm with spawner transforms from a simple poultry plot into a shining example of agricultural innovation — proof that even chickens can benefit from a little high-tech wizardry. After all, what’s more satisfying than a farm that practically runs itself, leaving you free to dream of bigger poultry ambitions?

Optimal Layout and Space Utilization

Designing an efficient chicken farm with spawner begins with a carefully planned layout that maximises space utilisation and promotes smooth workflow. The goal is to create an environment where chickens can thrive without the clutter and chaos often associated with traditional setups. A well-optimised layout ensures each component — from the spawner to feeding systems — works in harmony, boosting productivity and reducing unnecessary effort.

In a chicken farm with spawner, strategic placement is crucial. Positioning the spawner centrally allows for maximum coverage, ensuring chickens are consistently generated within easy reach of automated feeding and watering systems. This not only minimises movement but also helps prevent overcrowding, which can lead to health issues and decreased output.

Efficient space utilisation can be achieved through thoughtful design choices. For example, stacking systems or modular enclosures can optimise vertical space, thereby accommodating more chickens within a limited area. Incorporating

- automatic feeders

- water dispensers

seamlessly into the layout reduces manual labour and keeps the poultry comfortable and well-nourished. When every element is meticulously positioned, the chicken farm with spawner becomes a testament to smart engineering, turning a simple poultry operation into a model of modern agriculture innovation.

Integration of Spawner Technology with Traditional Farming Methods

Integrating spawner technology into a traditional chicken farm transforms the landscape of poultry management, blending the age-old art of farming with modern innovation. Imagine a farm where the rhythmic hum of automated systems harmonises seamlessly with natural growth cycles—this is the promise of a well-designed chicken farm with spawner. The key lies in marrying the efficiency of automation with the nurturing environment chickens require to flourish.

Strategic placement of the spawner is the cornerstone of success. Positioning it centrally not only maximises coverage but also minimises movement, creating a sanctuary where chickens are generated effortlessly within reach of automatic feeders and water dispensers. Such thoughtful integration ensures the farm operates with a ballet-like grace, reducing manual labour and elevating productivity.

Furthermore, vertical stacking enclosures and modular layouts breathe new life into limited spaces, allowing for lush populations without sacrificing comfort or health. This symbiosis of space utilisation and technological finesse results in a chicken farm with spawner that embodies modern agricultural ingenuity—turning the routine into a captivating dance of harmony and efficiency.

Setting Up a Chicken Farm with Spawner

Selecting the Right Spawner Equipment

Setting up a chicken farm with spawner technology is no longer the stuff of sci-fi fantasies—it’s a game-changer for modern poultry enthusiasts. The right spawner equipment can turn a humble coop into a prolific egg-producing powerhouse, dramatically boosting efficiency and output. When selecting your spawner, focus on durability and adaptability; after all, nobody wants their chicken farm with spawner to turn into a mechanical nightmare.

A well-chosen spawner system seamlessly integrates with your existing farm layout, ensuring smooth operations and minimal downtime. Consider options like automated feeders or climate-controlled environments that optimise chicken health and productivity. Remember, the secret to a thriving chicken farm with spawner lies in matching the equipment to your specific needs—whether you’re aiming for large-scale commercial success or a sustainable backyard operation. With the right gear, you’ll be well on your way to poultry paradise!

Preparing the Farm Environment for Spawner Installation

Establishing a successful chicken farm with spawner technology begins well before flipping the first switch. The environment you prepare plays a pivotal role in harnessing the full potential of your spawner system. A carefully crafted farm environment not only safeguards your investment but also ensures consistent productivity and animal welfare. The goal is to create a space that promotes natural behaviours while optimising operational efficiency.

Preparation starts with assessing your available space and ensuring excellent ventilation. Proper airflow prevents the build-up of harmful fumes and maintains a stable climate—crucial for both chicken health and spawner performance. Additionally, laying a sturdy foundation for your equipment, such as automated feeders and climate controllers, facilitates seamless integration. Remember, the key to unlocking your chicken farm with spawner’s true potential lies in meticulous environment setup.

To streamline installation, consider the following steps:

- Clear and level the designated area to prevent mechanical issues.

- Install durable flooring that is easy to clean and resistant to moisture.

- Set up reliable power sources for automated systems and climate controls.

Installing and Configuring Spawners for Maximum Efficiency

Setting up a chicken farm with spawner isn’t just a matter of plugging in a device and hoping for the best. It’s a delicate dance of precision, where the placement and configuration of your spawner can make or break your poultry empire. Think of it as tuning a fine instrument—every component, from the power supply to the climate controls, must harmonise perfectly to maximise efficiency.

Start by positioning your spawner in a location that allows for unobstructed airflow and easy access for maintenance. A well-placed spawner ensures smooth operation, reduces downtime, and encourages natural behaviours among your chickens. To streamline the installation process, consider implementing a step-by-step approach:

- Secure reliable power sources to keep your automated feeders and climate controls humming along.

- Calibrate the spawner settings to match your farm’s specific needs, whether it’s hatch rate or nutrient output.

- Ensure the environment is optimised—think insulated walls, adjustable lighting, and smart ventilation.

Remember, the key to realising the full potential of your chicken farm with spawner lies not just in technology, but in thoughtful configuration—because even the most advanced spawner is only as good as the environment it operates within!

Managing and Maintaining a Spawner-Integrated Chicken Farm

Regular Maintenance and Troubleshooting

Maintaining a high-functioning chicken farm with spawner isn’t a task for the faint-hearted, but it’s rewarding when done right. Regular inspection and troubleshooting are crucial to keep those clucking machines running smoothly. A well-maintained spawner system can boost productivity, but neglecting minor issues could turn your farm into a feathered chaos.

One common challenge is ensuring the spawner’s components remain clean and free from blockages. Dust and debris can cause jamming or misfiring, leading to decreased hatch rates. Routine checks can prevent these hiccups, saving time and money.

For troubleshooting, it’s handy to keep a checklist:

- Inspect power connections and control mechanisms

- Monitor environmental conditions—humidity and temperature are the chicken farm with spawner’s best friends

- Calibrate the spawner settings periodically for optimal performance

A proactive approach to maintenance will keep your poultry operation thriving, transforming your chicken farm with spawner into a model of efficiency and innovation.

Monitoring Chicken Health and Productivity

Monitoring chicken health and productivity within a chicken farm with spawner demands a meticulous eye and an intuitive understanding of the farm’s delicate ecosystem. The spawner system, while revolutionary, introduces complexities that extend beyond mere mechanical operation; it intertwines with the biological rhythm of your poultry. Regular observation of behavioural cues—pecking patterns, activity levels, and vocalisations—can reveal early signs of stress or illness, preventing minor issues from escalating into catastrophic setbacks.

A critical aspect of managing a chicken farm with spawner is ensuring that environmental parameters—humidity, temperature, and airflow—remain within optimal ranges. These variables directly influence hatch rates and overall vitality. Implementing a structured monitoring protocol, such as daily visual inspections and recording environmental data, fosters a proactive approach that sustains high productivity levels. When the system is finely tuned, the symbiosis of technology and biology results in an efficient, flourishing poultry operation—proof that attentive management is the cornerstone of modern chicken farming.

Optimizing Spawner Performance for Sustainable Output

In the shadowed corridors of a well-tuned chicken farm with spawner, the true art lies in maintaining a delicate equilibrium—where technology and nature entwine in a dance of perpetual renewal. To optimise spawner performance, vigilant oversight becomes paramount. Every cog, every parameter, must be calibrated with precision to sustain the symphony of life within. The secret to a thriving poultry operation often whispers in the quiet moments of routine maintenance, where unseen minutiae can herald either prosperity or decay.

To ensure the resilient vitality of your flock, consider implementing a routine that includes:

- Daily checks of environmental conditions—humidity, airflow, and temperature—are vital to preserve the delicate biological rhythm.

- Regular cleaning and inspection of spawner components prevent the insidious buildup of debris that could sabotage productivity.

- Monitoring behavioural cues—such as pecking patterns and vocalisations—can reveal early signs of distress or disease.

Within the labyrinthine depths of a chicken farm with spawner, sustaining optimal performance requires more than mere mechanical adjustments; it demands a poetic balance of biological intuition and technological finesse. When harmony is achieved, the farm transforms into a sanctuary of sustainable output, where each component plays its part in an eternal cycle of rebirth and growth—an ode to the relentless pursuit of agricultural mastery.

Cost Considerations and Profitability

Initial Investment in Spawner Technology

Embarking on a chicken farm with spawner technology is akin to investing in a futuristic poultry utopia—except the price tag might make your wallet do a double take. The initial investment isn’t just about buying spawners; it’s the entire ecosystem—power supplies, specialised infrastructure, and the technical know-how—that demands a hefty upfront commitment. For those dreaming of a self-sustaining chicken farm with spawner, it’s crucial to crunch the numbers early on.

While the startup costs can seem daunting, the real magic lies in the potential for long-term profitability. Spawner systems turbocharge egg production and optimise chicken growth rates, turning what used to be labour-intensive chores into automated symphonies of efficiency. To gauge whether your investment will pay off, consider factors like feed costs, maintenance expenses, and market prices for poultry products. A strategic approach might involve starting small and scaling as profits accrue.

In fact, a well-planned chicken farm with spawner can yield a remarkable Return on Investment (ROI), especially when combined with optimal resource management. The key is balancing initial expenditure with sustained output—because in poultry farming, as in comedy, timing is everything! Remember, the true cost of spawner technology is not just monetary; it’s the promise of a future where poultry farming is less about sweat and more about smart, scalable automation.

Operational Costs and Savings

Cost considerations can make or break your dream of a chicken farm with spawner technology. While initial setup costs might seem like a hefty investment — think specialised infrastructure, power supplies, and the all-important spawner equipment — the real savings come down the line. Operational expenses, such as feed, routine maintenance, and energy consumption, can eat into your profits if not carefully managed. However, the automation provided by spawner systems often reduces labour costs significantly, allowing you to focus on scaling rather than slogging through chores.

To truly gauge profitability, it’s wise to analyse key factors like feed conversion efficiency, maintenance schedules, and market demand for poultry products. For instance, some chicken farm with spawner setups use ul

to cut down on ongoing costs. These smart investments not only optimise resource utilisation but also bolster the bottom line. With the right balance, a well-designed chicken farm with spawner can turn a modest initial expenditure into sustainable profit, proving that sometimes, automation is the chicken’s whiskers of poultry farming!

Economic Benefits of Using Spawners in Chicken Farming

In the complex world of poultry production, the financial landscape can be as unpredictable as a flock in flight. A chicken farm with spawner technology presents a fascinating blend of innovation and economic opportunity, but the real question lies in balancing costs with potential gains. While the initial investment in specialised infrastructure and state-of-the-art spawner systems might seem steep, the true economic benefits reveal themselves over time. Smart integration of automation can slash labour expenses, transforming what once required a dedicated team into a streamlined operation.

Cost considerations are no longer just about upfront expenditure—they extend into ongoing operational expenses. Feed efficiency, energy consumption, and maintenance schedules can significantly influence your profitability. For instance, employing energy-efficient lighting and automatic feeders in a chicken farm with spawner technology can optimise resource use and minimise waste. These strategic investments not only enhance productivity but also bolster long-term profit margins. The real magic happens when technology turns routine chores into automated processes, allowing farm managers to focus on scaling and innovation rather than day-to-day chores.

Understanding the economic benefits of using spawners in poultry farming involves recognising their impact on productivity and sustainability. The automation of egg collection and chicken rearing ensures consistent output and reduces the risk of human error. Additionally, the precise control over environmental conditions—such as temperature and humidity—keeps chickens healthier and more productive. These efficiencies translate into a higher return on investment, making a chicken farm with spawner a promising venture for those looking to enhance their poultry enterprise. It’s a calculated gamble that, with the right balance, can yield sustainable profit and even redefine the future of poultry farming.

Legal Regulations and Ethical Standards

Compliance with Farming and Animal Welfare Laws

Maintaining legal regulations and ethical standards in a chicken farm with spawner is not merely a matter of compliance; it is a moral imperative that defines our relationship with living creatures. Laws governing animal welfare and farming practices are designed to ensure that poultry is raised humanely, respecting their instincts and natural behaviours. Ignoring these standards risks not only legal repercussions but also the erosion of trust among consumers who increasingly demand transparency and ethical integrity.

In many regions, strict guidelines specify space requirements, access to natural light, and provisions for enrichment that prevent suffering and promote healthy development. Adherence to these regulations safeguards farm operators from costly penalties and reputational damage. Moreover, implementing ethical standards fosters a sustainable model where productivity and animal well-being coexist in harmony, reinforcing the fundamental purpose of a chicken farm with spawner — to produce high-quality poultry without compromising integrity.

Sustainable and Ethical Farming Practices

Legal regulations and ethical standards are the backbone of a successful chicken farm with spawner. In an industry where consumer trust is paramount, adherence to animal welfare laws isn’t just a legal requirement—it’s a moral one. High standards ensure that poultry is raised humanely, respecting their natural behaviours and instincts. This approach not only safeguards the welfare of the birds but also enhances farm reputation and marketability.

Regulatory guidelines often include specific provisions such as space requirements, access to natural light, and environmental enrichment. These measures help prevent suffering and promote healthy development. To maintain compliance, many chicken farm with spawner operators implement a strict protocol, which may include:

- Monitoring environmental conditions

- Providing adequate ventilation

- Ensuring proper feeding and watering systems

Meeting these standards creates a sustainable and ethical farming environment. It fosters a resilient operation where productivity aligns with the well-being of the poultry. Emphasising responsible practices not only minimises legal risks but also bolsters consumer confidence—key elements in today’s competitive poultry industry. In a chicken farm with spawner, integrating ethical standards with sustainable farming practices is vital for long-term success and integrity.

Safety Protocols for Farm Workers and Chickens

Maintaining strict safety protocols on a chicken farm with spawner is essential to protect both workers and poultry. Legal regulations mandate comprehensive measures that minimise risks and uphold high standards of animal welfare. These include proper handling procedures, protective gear, and clear hygiene practices—each contributing to a safer environment. Ensuring compliance isn’t just about avoiding penalties; it’s about fostering a culture of responsibility and respect within the farm community.

For farm workers, implementing rigorous safety protocols is non-negotiable. Regular training sessions, dedicated to recognising hazards and correct handling techniques, help create a workplace where everyone feels secure. Likewise, safeguarding the chickens involves measures such as controlled access to different areas, scheduled health checks, and strict biosecurity procedures. A chicken farm with spawner benefits immensely from these practices, as they directly influence productivity and animal well-being.

- Use of personal protective equipment (PPE)

- Consistent sanitisation routines

- Emergency response plans

Adopting these safety measures ensures a harmonious operation—where human safety and ethical treatment of poultry go hand in hand, reinforcing the farm’s reputation for responsible, sustainable agriculture. In a competitive industry, this commitment to safety and ethics builds trust, attracting conscientious consumers and dedicated staff alike.

Innovations and Future Trends in Chicken Farming with Spawners

Emerging Technologies in Poultry Farming

Innovation in poultry farming is no longer a distant aspiration but an unfolding reality, especially within the realm of chicken farm with spawner technology. As emerging technologies reshape the landscape, the potential for sustainable and efficient food production becomes palpably tangible. The future of chicken farming hinges on integrating intelligent systems that can adapt to environmental variables and optimise growth cycles with minimal human intervention.

One promising trend is the utilisation of automation and machine learning algorithms that monitor and adjust spawner operations in real time. These advancements enable farmers to enhance productivity while maintaining animal welfare standards. Furthermore, innovations such as biotechnological enhancements to spawner components promise longer lifespan and increased resilience against wear and tear. As we venture into this new era, the focus shifts toward creating a symbiotic relationship between technology and nature, ensuring ethical practices do not fall by the wayside.

In this context, the adoption of smart sensors and IoT devices within a chicken farm with spawner is revolutionising how we conceptualise poultry husbandry. These tools provide detailed insights into chicken health, feed efficiency, and environmental conditions, fostering a more sustainable approach. The trajectory suggests a future where farms are not merely utilising technology but are seamlessly integrated ecosystems that respond dynamically—driving efficiency, welfare, and ecological balance forward in unison.

Automation and Smart Farming Solutions

In the rapidly evolving world of poultry farming, innovation is no longer a distant dream but a tangible reality shaping the future of chicken farm with spawner technology. Automation and smart farming solutions are transforming traditional practices into high-efficiency ecosystems that respond dynamically to environmental cues. It’s fascinating how these advancements not only boost productivity but also uphold the highest standards of animal welfare, proving that technology and ethics can indeed dance in harmonious tandem.

Emerging trends such as IoT integration and machine learning algorithms are at the forefront of this revolution, allowing chicken farms with spawner systems to operate with unprecedented precision. For instance, real-time data from smart sensors can optimise feed delivery, regulate temperature, and monitor chicken health—minimising waste and maximising output. This seamless synergy between human ingenuity and technological prowess ensures farms stay ahead of the curve in sustainability and operational excellence.

- Automation systems that adapt to environmental fluctuations

- Biotechnological enhancements extending spawner lifespan

- Intelligent monitoring tools for health and productivity metrics

These innovations herald a new era where farms become increasingly intelligent, interconnected entities—driven by data, yet rooted in ethical responsibility. The integration of such cutting-edge solutions within a chicken farm with spawner not only elevates efficiency but also exemplifies a commitment to sustainable and ethical poultry production. Truly, the future of poultry farming is here, and it’s resoundingly smart!

Potential Impact on Industry Standards and Practices

The dawn of technological innovation is transforming the landscape of poultry farming at an extraordinary pace. In particular, chicken farm with spawner systems are poised to revolutionise industry standards, ushering in an era where efficiency and sustainability coexist seamlessly. These advancements herald a future where farms are not merely utilitarian spaces but vibrant ecosystems driven by intelligent machinery and data-driven insights.

Emerging trends such as AI-powered monitoring and IoT integration promise to elevate chicken farm with spawner setups into hyper-efficient hubs of productivity. As these technologies evolve, they will redefine what is achievable in poultry management—minimising waste, maximising output, and upholding the highest standards of animal welfare. The potential impact on industry practices is profound; farms will become more adaptive and environmentally responsible, paving the way for a sustainable poultry sector.

Innovations like biotechnological enhancements to extend spawner lifespan and sophisticated health monitoring tools are already shaping the future. These advancements not only improve operational efficiency but also set new benchmarks for ethical standards in poultry farming. As the industry embraces these cutting-edge solutions, the chicken farm with spawner will become a symbol of modern, responsible food production—an exemplar of what the future holds for sustainable, high-tech poultry farms.

0 Comments